UBC researchers discover way to reduce harsh chemicals in manufacturing rayon

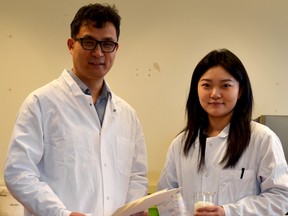

Developed by associate professor Feng Jiang and doctoral student Huayu Liu, the new method uses microfibrillated cellulose to reduce solvent use by up to 70 per cent

Last updated 6 hours ago

You can save this article by registering for free here. Or sign-in if you have an account.

Rayon has been popular for decades because of its soft cotton-like properties, but it also requires a lot of harsh chemicals to make.

Subscribe now to read the latest news in your city and across Canada.

- Unlimited online access to articles from across Canada with one account.

- Get exclusive access to the Vancouver Sun ePaper, an electronic replica of the print edition that you can share, download and comment on.

- Enjoy insights and behind-the-scenes analysis from our award-winning journalists.

- Support local journalists and the next generation of journalists.

- Daily puzzles including the New York Times Crossword.

Subscribe now to read the latest news in your city and across Canada.

- Unlimited online access to articles from across Canada with one account.

- Get exclusive access to the Vancouver Sun ePaper, an electronic replica of the print edition that you can share, download and comment on.

- Enjoy insights and behind-the-scenes analysis from our award-winning journalists.

- Support local journalists and the next generation of journalists.

- Daily puzzles including the New York Times Crossword.

Create an account or sign in to continue with your reading experience.

- Access articles from across Canada with one account.

- Share your thoughts and join the conversation in the comments.

- Enjoy additional articles per month.

- Get email updates from your favourite authors.

Create an account or sign in to continue with your reading experience.

- Access articles from across Canada with one account

- Share your thoughts and join the conversation in the comments

- Enjoy additional articles per month

- Get email updates from your favourite authors

Sign In or Create an Account

Now a team of researchers from the University of B.C. have developed a more sustainable way to make rayon, a semi-synthetic fabric made from wood pulp.

In a peer-reviewed study, published in the journal Chem Circularity, a UBC associate professor of forestry, Feng Jiang, and a doctoral student, Huayu Li, present a way to cut solvent use in making rayon by up to 70 per cent.

The textile industry urgently requires sustainable alternatives to petroleum-derived fibres like polyester and nylon, Jiang said Tuesday.

Rayon is better but it’s usually made using carbon disulphide, which is toxic and cause a range of health problems to the nervous and cardiovascular systems and even cancer, he said. Used solvents have been tossed out, making production environmentally unsustainable.

“So our goal was to find an alternative way to produce a fibre like rayon for the textile industry that has similar properties but less toxicity,” said Jiang.

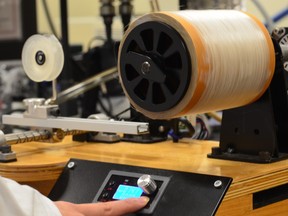

So instead of dissolving all the wood pulp with the toxic chemical, they used microfibrillated cellulose, which are thin strands made by grinding down wood pulp.

The process involves spinning cellulose at room temperature using a non-dissolving solvent, reducing energy consumption and chemical costs.

He said the strands could also come from other sustainable pulp, for example hemp or grass.

However, Jiang said their new process means that rayon could join the list of environmental sustainable choices for fabrics, a win for the environment and the fashion industry.

“Our method is a closed loop, or circular processing. So all the ingredients or the chemicals we are using can be recycled and reused,” said Jiang.

“It’s just like paper and will eventually break down in the environment so in that case there’s no difference with the traditional rayon, which is naturally biodegradable.”

Cloth made of rayon has soft, natural-feeling texture like silk or cotton, which Jiang says makes it a desirable material for clothing but also for products like diapers.

Future plans include collaborating with Kwantlen Polytechnic University for testing and prototyping, and to explore alternative fibre sources like hemp and straw.

Jiang said they’d eventually like to scale up production and create fabric using B.C. fibre.

“I think this would be very good for the local economy,” he said.